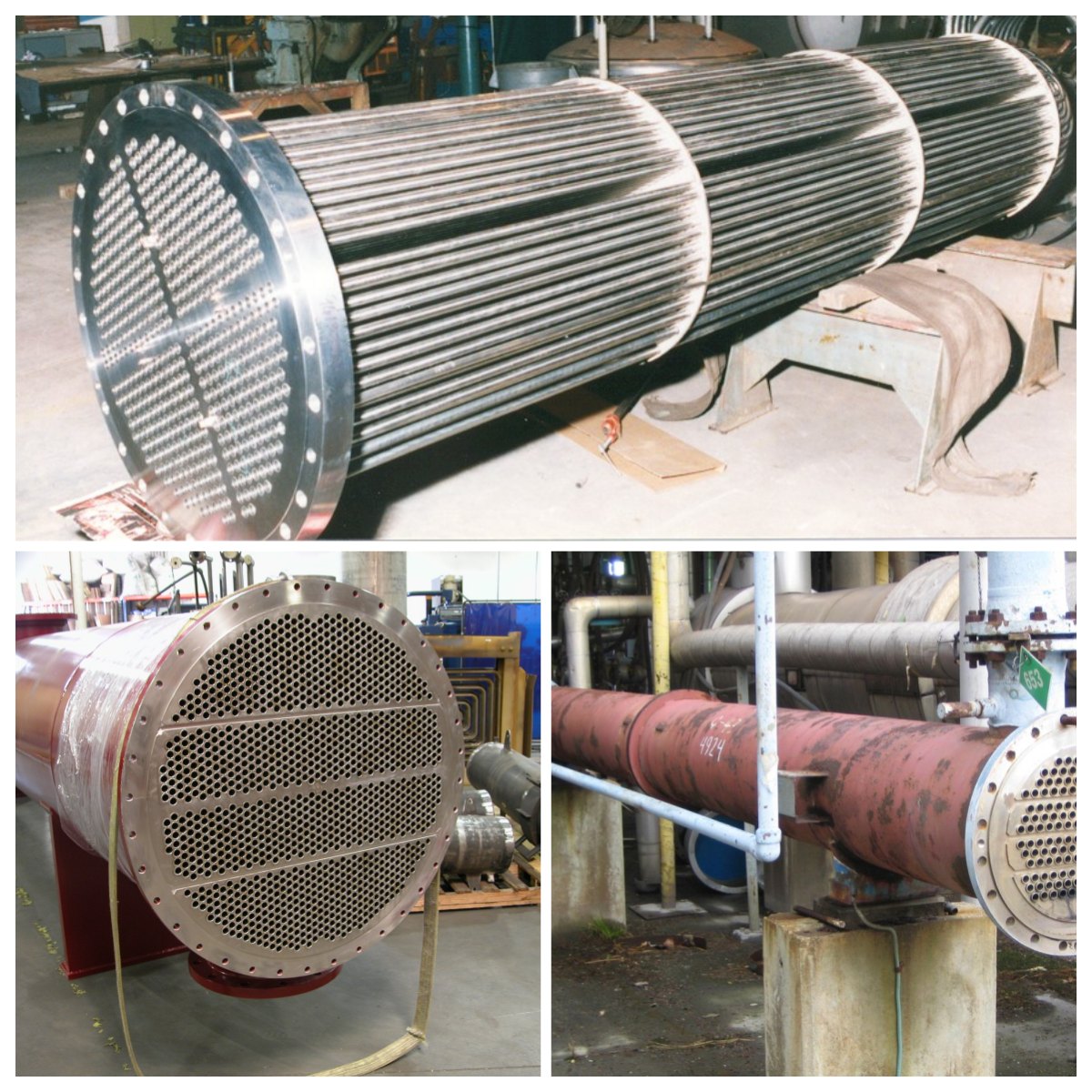

A tube sheet is a critical component in many types of heat exchangers, providing structural support for tubes and ensuring proper fluid separation. Understanding its design, materials, applications, and maintenance is essential for maximizing heat exchanger performance and lifespan.

A tube sheet (or tubesheet) is a thick metal plate with precisely drilled holes that hold and support heat exchanger tubes. It serves two primary functions:

Structural Support – Keeps tubes firmly in place during operation.

Fluid Separation – Prevents mixing between shell-side and tube-side fluids.

Tube sheets can be fixed or floating, depending on the heat exchanger design. They are used in shell-and-tube heat exchangers, boilers, condensers, and other heat transfer equipment.

Material selection depends on temperature, pressure, and corrosion resistance requirements. Common options include:

Carbon Steel – Cost-effective and strong, suitable for non-corrosive environments.

Stainless Steel (304, 316, Duplex) – Excellent corrosion resistance for chemical and marine applications.

Copper Alloys – Good thermal conductivity and moderate corrosion resistance.

Nickel Alloys (Inconel, Monel) – High resistance to heat and aggressive chemicals.

Titanium – Exceptional seawater and chloride resistance.

Clad Tube Sheets – Base carbon steel with a corrosion-resistant alloy layer to balance cost and durability.

Tube sheets are used in a variety of industries and equipment types:

Power Plants – Boilers, condensers, and feedwater heaters.

Petrochemical Industry – Heat exchangers in refineries and chemical plants.

Marine Industry – Seawater-cooled condensers and evaporators.

HVAC Systems – Chillers and industrial air conditioning units.

Desalination Plants – Multi-effect distillation and reverse osmosis systems.

Fabricating a tube sheet involves precision engineering to ensure durability and fit:

Material Cutting – Selecting and cutting the base metal plate.

Drilling – CNC or laser drilling of tube holes for accuracy.

Grooving or Expanding – Creating grooves for mechanical tube expansion.

Cladding (if required) – Applying a corrosion-resistant alloy layer.

Heat Treatment – Stress-relieving to improve mechanical properties.

Inspection – Dimensional checks, ultrasonic testing, and surface finish inspection.

To maintain performance and extend lifespan:

Regular Inspections – Look for pitting, erosion, and corrosion.

Cleaning – Remove scale, debris, and fouling from tube ends and surfaces.

Re-Tubing – Replace worn or corroded tubes while reusing the tube sheet if possible.

Welding Repairs – Apply overlay welding to restore corroded cladding.

Protective Coatings – Use epoxy or thermal spray for added corrosion resistance.

When selecting materials, consider:

Temperature Range – High-temperature alloys for extreme heat.

Corrosion Resistance – Stainless steel, titanium, or nickel alloys for aggressive environments.

Pressure Requirements – Materials with high tensile strength for high-pressure operations.

Fluid Compatibility – Avoid galvanic corrosion by matching tube and tube sheet materials.

Budget Constraints – Use cladding to balance cost and performance.

A thorough analysis of process conditions, maintenance intervals, and lifecycle costs will help choose the optimal material.

Conclusion:

The tube sheet is a vital element of heat exchanger design, directly affecting efficiency, durability, and maintenance needs. With the right material selection, precise fabrication, and consistent upkeep, tube sheets can provide decades of reliable service in demanding industrial environments.

Previous

Comments

Please Join Us to post.

0